When fit testing it is critical that all details are correct, and reliable. This post will discuss inputting new RPE into the FitPro Ultra software, and help you avoid making mistakes when doing this. We will also provide some examples of some correctly inputted common respirators.

Getting started

When adding new RPE into FitPro Ultra for fit testing, we are required to assign the correct manufacturer, model, style, pass level and optionally, approval standard, as well as selecting the filtering efficiency (N95 or non-N95).

Where do I find this information?

Often, all this information is on the respirator itself, however it may be difficult to find on some respirators. When this is the case, we would recommend going to the respirator’s product leaflet/manufacture’s specifications/technical specifications if available, which will usually give all the information necessary. Do not take a guess at the details of the mask as this may lead to incorrect mask descriptions.

N95 on or off?

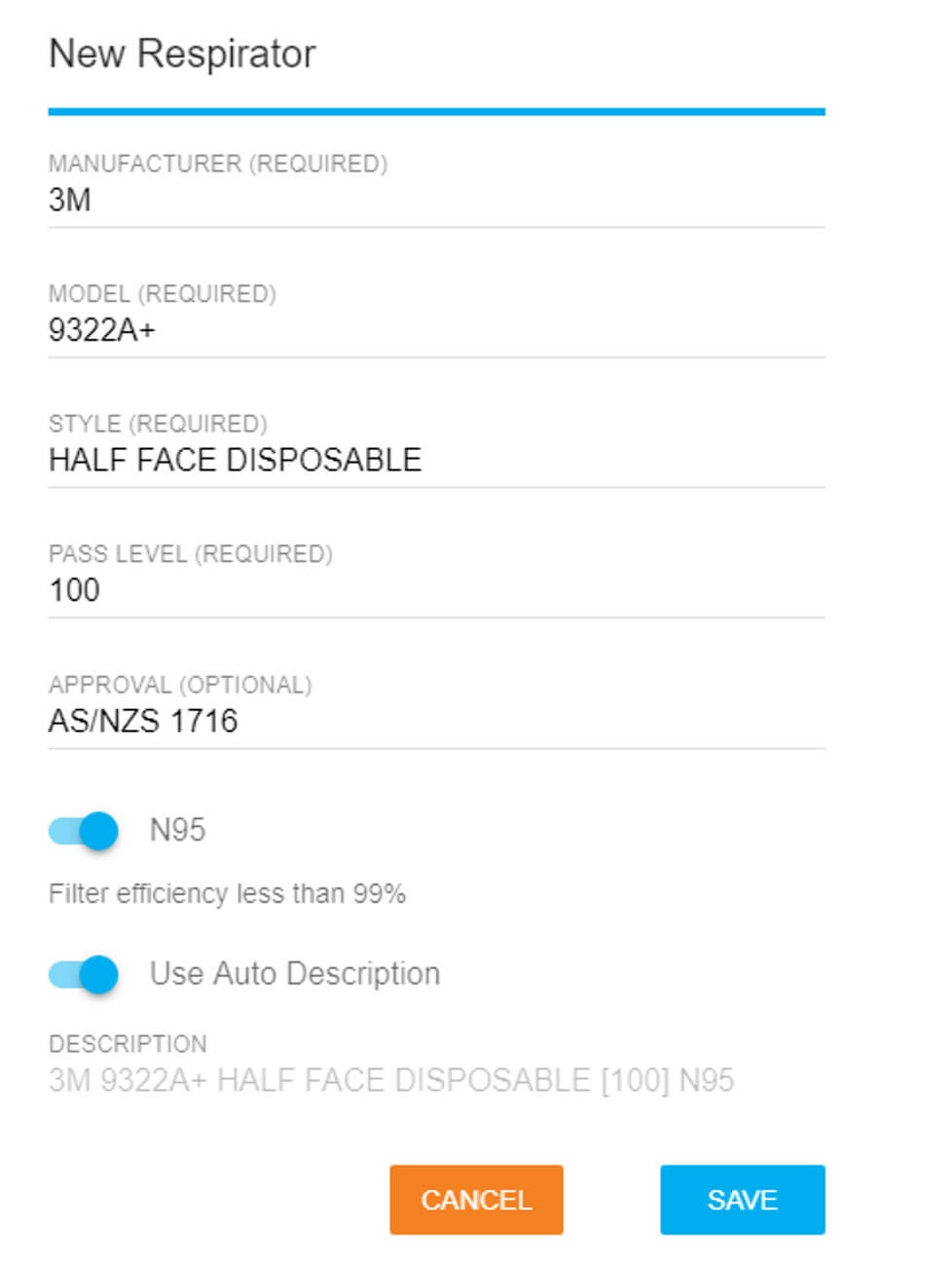

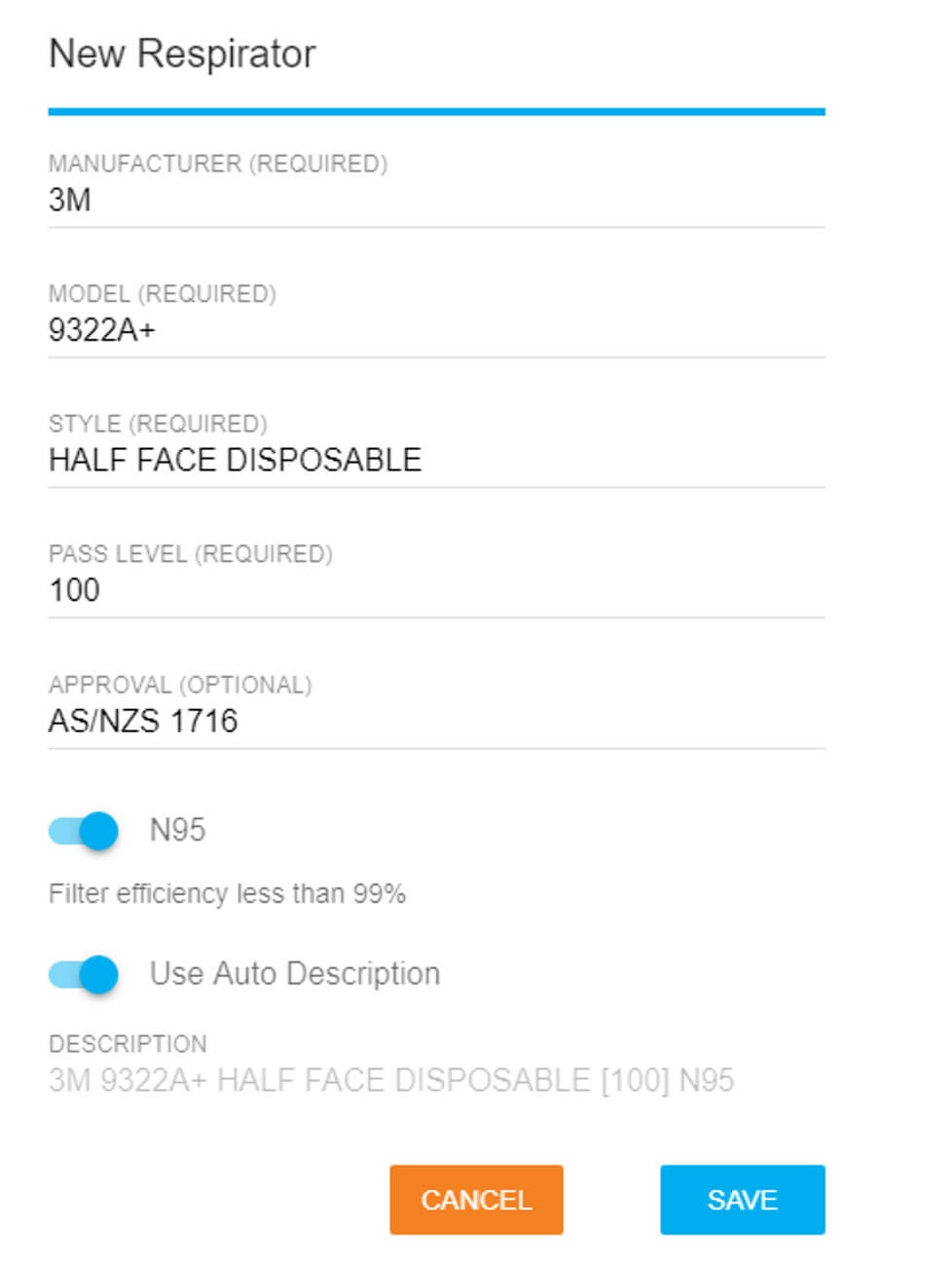

If a respirator has a filtering efficiency of less than 99%, such as the 3M 9322A+ (Image 1) or Halyard 46727 (Image 2), you should turn on N95 mode. This accounts for the lower filtering efficiency. If this is not done, you will likely see falsely failed results.

3M 9322A+

Image 1

Halyard 46727

Image 2

Remember that if a respirator is compatible with P3 filters, even if it comes with P2 filters, or will be used with P2 filters, P3 filters should be used for the test, and N95 mode should not be selected when inputting the respirator. An example of this is the 3M 6225 kit, which will be discussed below.

A less common occurrence is a disposable respirator with a FFP3 classification, which should not have N95 mode on, but should still be tested as a disposable respirator with the OSHA FAST-FILTERING FACE protocol or the OSHA 1910.134 (see our Modified Fit Test Protocols blog post for more details).

Something else to note on Images 1 and 2 is the optional approval standard, which will differ between respirators, or may be absent.

Does model = size?

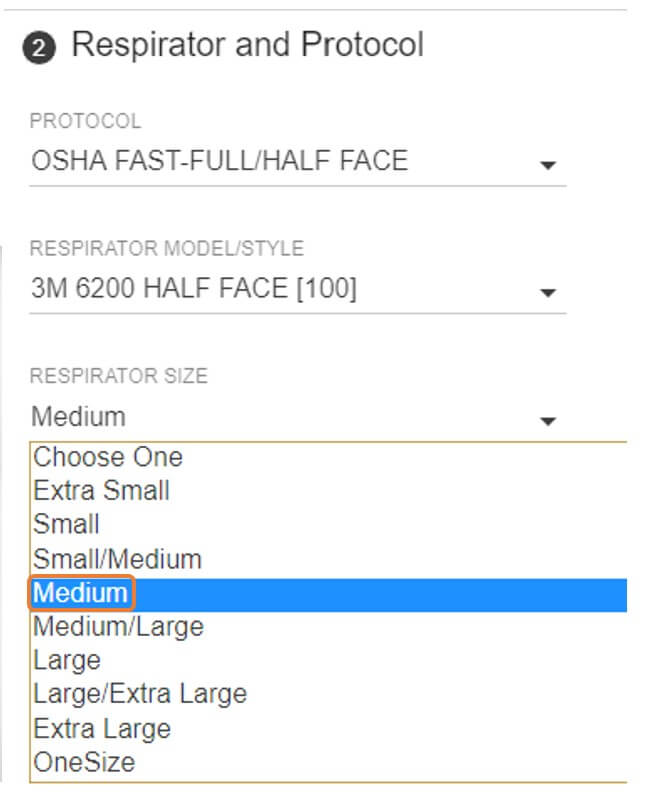

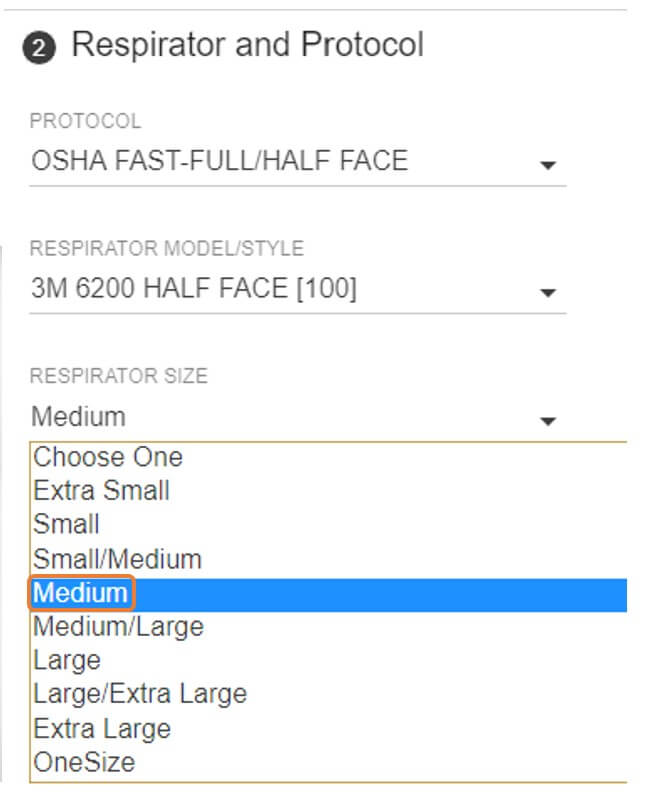

Many respirators will have a model for a specific mask, with no variation on this mask. An example of this is the 3M 6000 half face range (which comes in the 3M 6225 kit), with the models 6100, 6200 and 6300 corresponding with Small, Medium, and Large respirators respectively. When selecting a respirator for a test, the corresponding allocated size must be selected.

For example, after inputting a 3M 6200 into our Respirator database (Image 3), we will select “Medium” as our “Respirator Size” before beginning testing (Image 4).

Image 3

Image 4

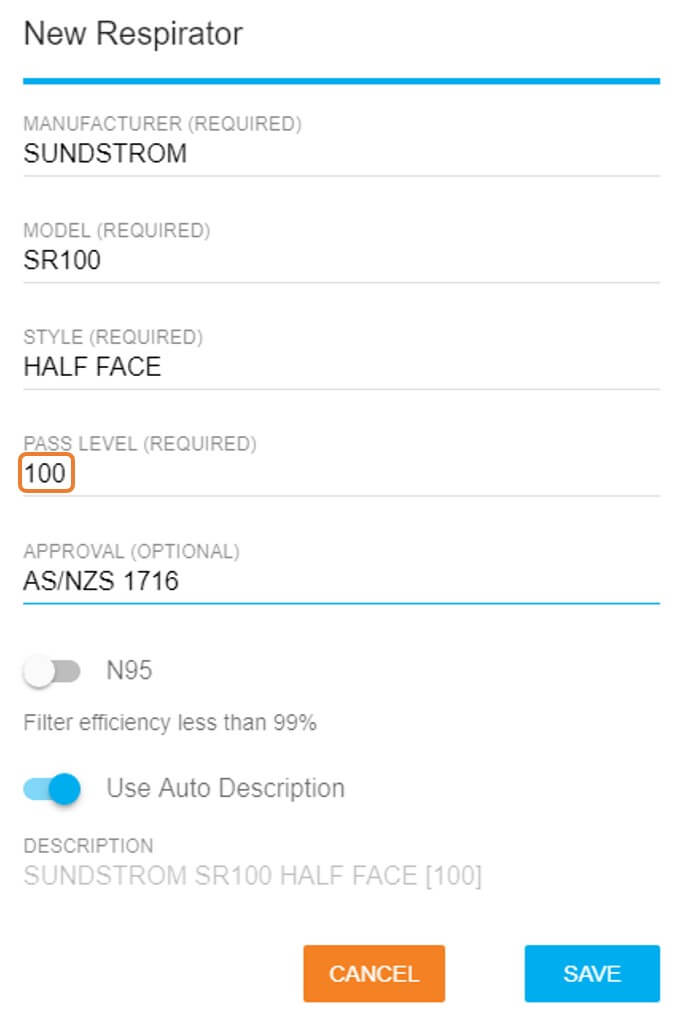

For certain respirators, they will have a model with multiple possible sizes. An example of this is the Sundstrom SR100, which is manufactured in the sizes Small/Medium, Medium/Large and Large/Extra-Large. For this specific respirator, this information is indicated on the underside of the respirator behind the filter, and by the respirator’s colour.

The respirator itself is to be added in the “Respirators” tab (Image 5), and when selecting the respirator for a test, the size must be selected (Image 6). In Image 5, we also see the same “Pass Level” as the rest of our half face respirators – 100, which is 10 times their Protection Factor of 10.

Image 5

Image 6

Are pass levels the same for all respirators?

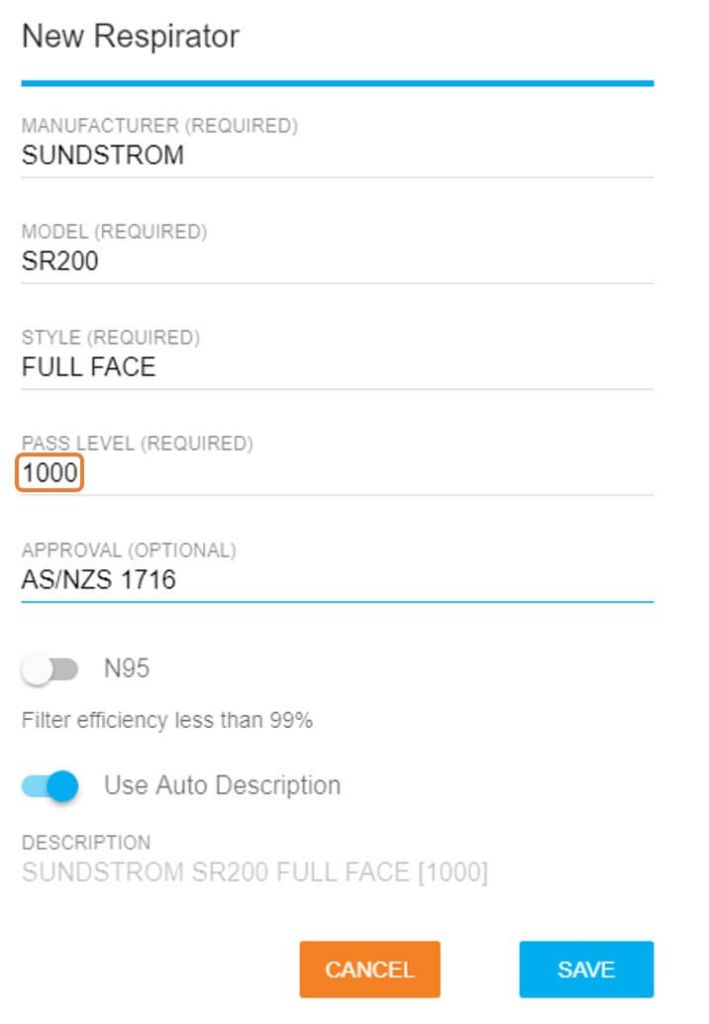

The final example will be a full face respirator, the SR200. The “Pass Level” will be different for different respirator styles. For the Sundstrom SR200 full face respirator, the “Pass Level” of 1000 is used, being 10 times the offered Protection Factor of 100, when worn with P3 filters (Image 7).

It is also important when selecting the respirator before testing to be aware that some respirators only come in one size, such as the SR200 (Image 8), so this should be selected when testing the SR200.

Image 7

Image 8

Should I double check all RPE entries?

When fit testing, it is common to get into a rhythm and overlook small errors. We always recommend ensuring that when RPE is added to your software, it has been added correctly (N95 correctly selected, all details accurate, correct spelling, correct capitalisation, naming conventions consistent).

Also be careful when in the field and adding RPE in, it is common to be in a hurry and this is when mistakes are made. Simply slow down, validate your reports as you test, always check all details and your testing will be of high quality and reliable.

How we streamline adding RPE?

When we complete bulk fit testing for mining companies/councils/healthcare using multiple laptops, we will generally form a database on each laptop, and then add all RPE to one database. This database is then exported and RPE is imported to all other laptops. This speeds up the process and ensures that all RPE is added in a consistent way.

We are always careful when establishing the first database and we always triple check all RPE added.

Wrap Up

This quick guide should get you started on inputting your RPE into FitPro Ultra. This blog post should not be substituted for the manufacturer’s specifications, company guidelines or Quantitative Face Fit Testing Training.

We can assist with all your fit testing and RESP-FIT training needs. We specialise in fit testing in Brisbane, and surrounds, and providing RESP-FIT approved training.

Get in contact with us by either calling 1300 336 003 or via our contact page.